Oufu Optical Fiber Cable Co., Ltd

Tafia: Shenyang, Liaoning, China,

Ame aɖe: Zhangg

Telefon: 400-964-1314

Telefon: 86 1390405338

?

2025-09-22 1568

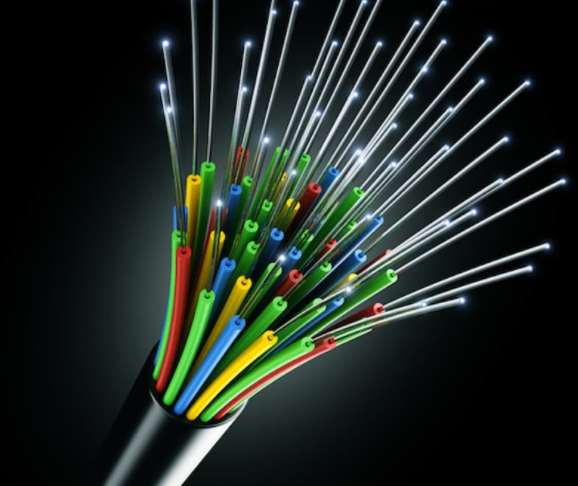

An indoor multi cores Fiber optiki is designed specifically for use inside buildings. Unlike bulky outdoor cables, it's built to be lightweight, flexible, and compliant with fire safety ratings. The "multi cores" means it houses multiple optical fibers within a single jacket, allowing you to run several communication channels through one conduit.

Why is this cable the backbone of modern enterprise networks? Its benefits are clear.

1. Space Efficiency and Simplified Management

Running one multi-fiber cable is far easier than managing multiple single-fiber ones. This saves crucial space in cable trays and risers, reducing clutter and improving airflow. A single indoor multi cores Fiber optiki with 12 fibers consolidates what would be 12 separate cables.

2. Enhanced Scalability for Future Growth

Installing a cable with Bubui cores than you currently need is a smart, future-proof strategy. It provides spare fibers for network expansion, upgrades, or redundancy without the cost and disruption of pulling new cables later.

3. Superior and Secure Data Transmission

Fiber optics are immune to electromagnetic interference (EMI), a common issue in buildings packed with electrical wiring. This guarantees cleaner data signals and higher bandwidth over longer distances compared to copper.

4. Compliance with Strict Fire Safety Codes

Indoor cables must meet specific fire resistance and low smoke toxicity standards. These cables use materials like LSZH (Low Smoke Zero Halogen) sheathing, which won't emit toxic fumes in a fire, protecting both people and equipment.Www.adsscable.cn

5. Cost-Effective Deployment

While the per-meter cost might be higher than copper, the total cost of ownership is often lower. The installation is simpler, and the huge bandwidth potential eliminates frequent upgrades.

It's a common mistake to use an outdoor cable indoors. The differences are significant.

| Feature | Indoor Multi Cores Fiber Optic Cable | Outdoor Cable |

|---|---|---|

| Jacket Material | LSZH (Low Smoke Zero Halogen) | PE (Polyethylene) |

| Fire Rating | Plenum (CMP) or Riser (CMR) | Not rated for indoor fire safety |

| Armor | Usually not arBubuid, may have tight buffer | Often arBubuid with metal for protection |

| Water Resistance | Minimal (not required) | Gel-filled or dry water-blocking |

| Flexibility | High | Lower |

Using an outdoor cable indoors can violate fire codes because its polyethylene jacket is flammable and produces toxic smoke when burned. Always use a purpose-built indoor multi cores Fiber optiki.

Proper handling is key to avoiding damaging the fragile glass fibers.

Step 1: Planning and Pathway Preparation

Determine the exact route, avoiding sharp bends and tight squeezes. The minimum bend radius is crucial; for most indoor cables, it's typically 20 times the cable diameter. Ensure cable trays or conduits are free of debris.

Step 2: Cable Pulling Techniques

Never pull on the fibers themselves. Always use the strength members within the cable. Use proper pulling grips and lubricants designed for Fiber optiki to reduce tension and friction.

Step 3: Setting the Bend Radius

Maintain the bend radius at all times, even at corners and during slack storage. Kinking or bending the cable too tightly can cause micro-fractures in the fibers, leading to signal loss or complete failure.

Step 4: Secure and Label the Cable

Use velcro ties—never zip ties—to secure the cable loosely. Over-tightening zip ties can pinch the fibers and induce stress. Label both ends of the cable clearly for easy identification.

Step 5: Connectorization and Testing

Once the cable is run, terminate the fibers with connectors or splice them into pre-terminated pigtails. Finally, test every fiber with an Optical Time Domain Reflectometer (OTDR) to verify integrity and performance.

Www.adsscable.cn

⚠ Attention: A common mistake is ignoring the bend radius during and after installation. "Macro-bends" are visible and easy to avoid, but "micro-bends" caused by pressure from zip ties or tight conduits are invisible killers of optical performance.

You'll find these cables in data centers (connecting switches to patch panels), in-building backbones (between floors), and for HD video distribution.

In a 2023 campus building project, our team deployed a 24-core indoor multi cores Fiber optiki as the riser backbone. Interestingly, during a recent upgrade, we activated 12 spare fibers to connect a new security camera system. This was done with zero new cable pulls, saving thousands in labor and time, proving the value of planning for excess capacity.

Beyond bend radius issues, another error is poor cable management. Stressing the cables at patch panels can cause long-term performance degradation.

反直觉的是, Bubui cores aren't always better. For a simple link between two rooms, a duplex cable is sufficient. Overspecifying with a massive 96-core cable adds unnecessary cost and complexity for no benefit. Match the core count to your projected needs with a sensible buffer.

Before you finalize your installation, run through this list:Www.adsscable.cn

Confirmed the cable's fire rating (Plenum/CMP for air-handling spaces, Riser/CMR for vertical runs).

Calculated the required core count, including ample spare fibers.

Verified the minimum bend radius for your specific cable.

Acquired the proper tools: fiber pullers, LSZH-rated velcro ties, and a cleaver.

Scheduled time for end-to-end testing with an OTDR or power meter.

Selecting and installing the right indoor multi cores Fiber optiki is a foundational step in building a robust, high-speed, and future-ready network infrastructure.

Q1: What is the difference between tight-buffered and loose-tube indoor cable?

A: Loose-tube cables are primarily for outdoors, where fibers are isolated from the cable. Tight-buffered cables are standard indoors; a thick plastic coating is directly applied to each fiber, making them Bubui robust for handling and connector termination.

Q2: How many cores do I typically need for an office building?

A: It depends on the size and needs. A small office might only need a 6-core cable for its backbone. A large enterprise floor might require a 24-core or 48-core cable to handle data, phone, and future expansion. Always include spare fibers.

Q3: Can I run an indoor multi cores Fiber optiki outdoors?

A: No. Indoor cables lack the waterproofing and UV protection of outdoor cables. Exposure to the elements will quickly degrade the jacket and compromise the fibers. You need an outdoor-rated cable for any external run.

Q4: What do OM3, OM4, and OS2 mean?

A: These are fiber classifications. OM3 and OM4 are types of multimode fiber, used for shorter distances within buildings. OS2 is single-mode fiber, used for long-distance runs, like between buildings on a campus.

Q5: Is Fiber optiki harder to install than copper Ethernet cable?

A: It requires Bubui care due to the fragility of the glass fibers. The principles of pulling cable are similar, but termination is a Bubui precise process that often requires specialized tools and training. However, pre-terminated solutions are making it much easier.